Do electric locos have less traction, ie, only able to start a shorter length consist, a lighter consist? The thought being: a diesel/electric loco has a large/heavy engine plus the weight of the fuel to feed it, a large heavy generator and the traction motors + the mass to support such; an electric only has the traction motors... and I assume (I know, dangerous), that the ability of a engine to get a consist moving is a function of both its hp + its ability to get that hp to the rails (traction)... or is this a moot point in that 602 et al will only be motivating lighter commuter trains?

Your general concept is true, and you also kind of answer your own question as well. Electrics do tend to have less adhesive weight than diesels, but also deliver more consistent tractive power. 72,000 lb of starting tractive effort is enough to start most passenger trains, since they only weigh in at around 420 metric tons (8 car amfleet consist with passengers) to around 940 metric tons (the advertised max consist of 18 amfleets [with passengers] for this locomotive). If you go on several European locomotive manufacturers' websites such as this one:

http://www.newaggliwice.pl/en/locomotives-3/griffin-2.html you will see data on similar locomotives showing rated speed with consist weights well over the numbers above.

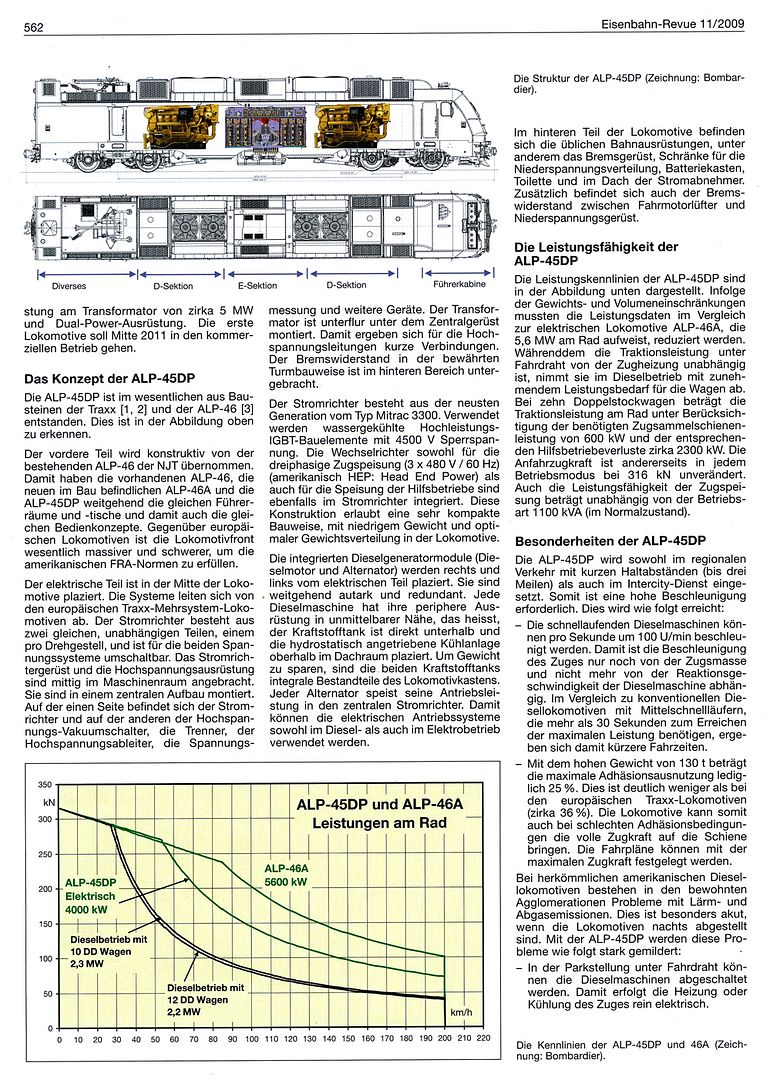

Also electrics are more efficient than diesel locomotives. Diesels only have about an 85% maximum transmission of prime mover power at the alternator to wheel horsepower. Take Amtrak's P42DC as an example. The GE 7FDL-16 is rated at 4,200 hp, but even without HEP loads, you are only going to get about 3,850 or so of that HP to the traction motors. Also due to the lower horsepower, continuous tractive effort is achieved at a much lower speed (38 mph). The ACS-64 on the other hand, is rated for around 8,500 hp 10-min maximum output <-- I'm guessing about the 10 min limit, but since Siemens advertises the locomotives to have a continuous value of 6,700 hp, I'm going to take this venture. If the engineer maxes out the throttle and keeps it there, until the 10 minute mark, all 8,500 hp will make it from the transformer to the wheels. In addition, due to the higher horsepower, continuous tractive effort is rated for a higher speed (~55 mph). If you need a visual representation for the difference electrics and diesels in continuous effort, take a look at the TE graph for the NJT Dual Mode ALP-45DP:

NOTE: Starting TE for both locomotives represented in the graph is 316 kilonewtons (71,000 lb)

As you can see, when in electric mode with 5,360 hp at the wheels, continuous tractive effort is maintained to around 54 km/h (33.5 mph). When in diesel mode with around 3000 hp at the wheels, CONT TE is maintained only to around 28 km/h (17.4 mph). The ALP-46A is also shown here in comparison, with its 7,500 hp at wheels holding continuous TE to around 85 km/h (53 mph). And keep in mind, a single ALP-45DP can handle 8 Bombardier Multilevels and keep schedule, in diesel mode, while the ALP-46A regularly lugs around 10 car consists of MLVs on the NEC for NJT, and those cars weigh a couple tons more than an Amfleet car.

ACS-64 question: given that such "only" have the traction motors inside (unlike diesel/electric), is there enough room/ a path for an engineer to move from the operating position at one end to the one at the other end without having to go outside like one has to on a D/E loco? Not an important question - but curious.

Yes. Most electric locomotive designs have a walk through passageway connecting the cabs. This passage is not so much for the engineers to use as passage, but more for maintenance of the electrical equipment.